In industrial fluid control systems, the ball valve seat is one of the most critical components that ensures tight sealing, smooth operation, and long-term reliability. Whether in oil & gas, chemical processing, power plants, or water treatment facilities, the performance of a valve is only as strong as its seat design. Choosing the correct ball valve seat material and design is essential for safety, efficiency, and cost-effectiveness. This guide provides a comprehensive overview of ball valve seat types, materials, design considerations, and replacement guidelines, helping engineers, procurement teams, and maintenance professionals make informed decisions.

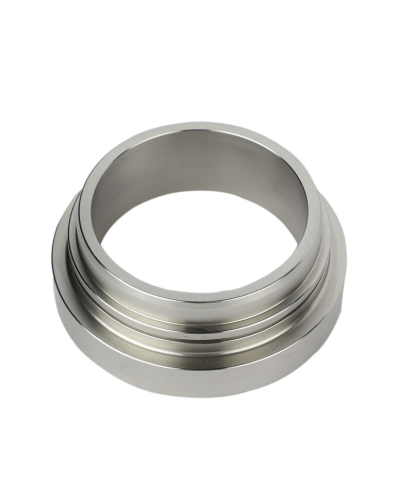

A ball valve seat is the component inside a ball valve that forms the seal between the spherical ball and the valve body. It ensures zero or minimal leakage when the valve is closed and allows smooth rotation when the valve is opened.

Ball valve seats can be manufactured from soft polymers (like PTFE or PEEK) or hardened metals (like stainless steel, Stellite, or Inconel). The right ball valve seat material selection guide depends on the pressure, temperature, fluid type, and application environment.

Key features of a ball valve seat include:

Sealing performance : Preventing fluid or gas leakage.

Durability : Resistance to wear, corrosion, and temperature changes.

Serviceability : Ease of ball valve seat replacement during maintenance.

Soft-seated valves use polymer-based materials like PTFE, R-PTFE, Nylon, and PEEK.

Advantages: Bubble-tight sealing, low torque, excellent chemical resistance.

Applications: Water treatment, HVAC, clean gas distribution.

Ball valve seat vs. seal: Soft seats serve both as a seal and a support surface.

Metal seats use hardened materials such as stainless steel, Inconel, or Stellite.

Advantages: Withstand extreme temperatures, abrasive fluids, and high pressures.

Applications: Oil & gas pipelines, refineries, slurry handling, power plants.

Note: Higher cost but longer service life.

These designs use springs to maintain constant contact between the ball and seat.

Advantages: Reliable sealing at low pressure, compensates for thermal expansion.

Applications: Cryogenic services, low-pressure gas systems.

Self-relieving seats automatically release cavity overpressure caused by trapped media.

Advantages: Prevents seat damage, enhances safety.

Applications: Natural gas pipelines, chemical plants.

DBB seats provide two independent seals for superior isolation.

Advantages: Enhanced safety, allows cavity venting without leakage.

Applications: Offshore platforms, refineries, and critical isolation systems.

Fire-safe seats incorporate a secondary metal-to-metal seal that activates when the soft seat burns or melts.

Advantages: Safety in fire emergencies, API 607 & ISO 10497 compliance.

Applications: Oil & gas, petrochemical, and refinery environments.

Designed for extremely low temperatures (down to -196 °C).

Advantages: Prevents leakage from thermal contraction, ensures safe LNG handling.

Applications: LNG plants, aerospace, cryogenic liquid transport.

Soft seats: Moderate conditions, bubble-tight sealing.

Metal seats: Extreme pressure/temperature, abrasive media.

Always check the ball valve seat material against system pressure-temperature ratings.

Clean fluids/gases: Soft seats are sufficient.

Abrasive slurries: Require durable metal seats.

Corrosive chemicals: PTFE or PEEK for high chemical resistance.

Zero leakage required: Soft-seated ball valve seats.

Controlled leakage acceptable: Metal-seated valves in harsh environments.

Fire-safe seats: Required for hazardous industries.

DBB designs: Offer added safety isolation.

Cryogenic seats: Must comply with LNG safety standards.

Soft seats: Lower cost, more frequent replacement.

Metal seats: Higher cost, longer service life.

Regular ball valve seat replacement schedules reduce downtime.

Floating ball seat design: Simple but higher torque under pressure.

Trunnion-mounted seat design: Uses springs to reduce torque, ideal for large valves.

Cryogenic LNG systems: Need cryogenic seats.

High-dust or slurry environments: Metal seats are better.

Clean room/pharma use: FDA-approved soft seats.

The ball valve seat is more than just a sealing element—it determines the reliability, safety, and lifecycle cost of your entire valve system. By evaluating seat types, materials, operating conditions, safety requirements, and maintenance needs, engineers and buyers can select the best design for their applications. For industries that demand durability, safety, and precision, GOTEB Ball Valve Seat solutions stand out with proven performance and versatile material options. Whether you need ball valve seat installation, replacement, or material selection guidance, GOTEB offers a reliable answer.